I launched the 3rd plug back on the pass side last week and decided instead of waiting 2 weeks for ford to fix it I was just going to put an insert in.

I got the info for the kit here :- http://www.timesert.com/html/howtosp.html

And ordered it here :- http://www.threadkits.com/

I got kit # 4412e with insert #s 44185 and 44186, one is slightly longer than the other and I was told by different people to use different ones so I just ordered both! It turns out 44186 was pretty much perfect and 44185 as a little short. Total cost came to just under $150 shipped.

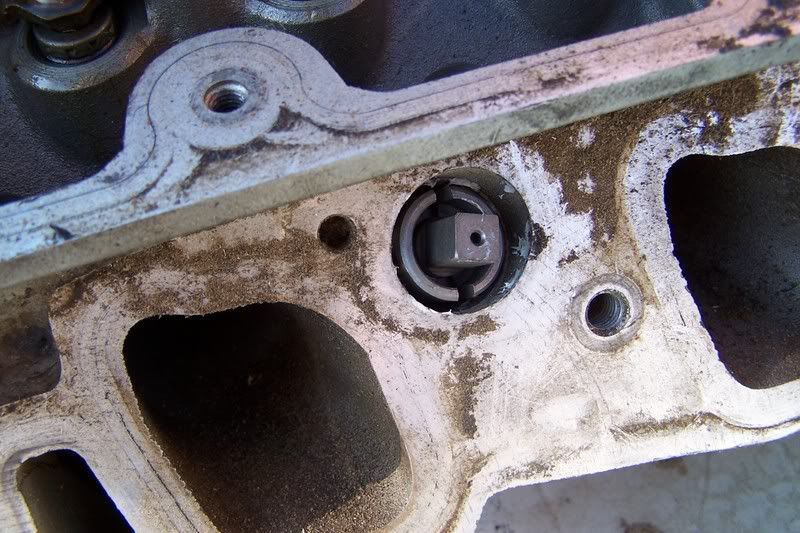

Heres is part of the kit and the inserts :-

I used an old head from a blown motor so I could get some decent pics and some practice before I tried it on my baby.

Reply With Quote

Reply With Quote